Whistory

Whistle collecting has grown slowly but steadily for many years. However, this has been despite unrecorded organized research. Usually this was made up of independent disconnected sources and therefore lacking when it comes to a community of whistle students.

However, with the advent of the internet has come great strides. This has been driven because of commerce and followed by the use of public platforms. Additionally, the ease with which electronic pictures can be taken with high resolution even with a phone camera that are readily posted and exchanged has expanded communication tremendously.

The challenge arises when verifying that all are one the same page from discussion to discussion. Therefore, an agreed upon whistle language is not only necessitated, but energizes the field of whistology – the study of whistles.

For the best communication, it therefore requires knowing the basics of what goes into making the whistles, not that you need a college degree, but just to be able to talk whistles easily with one another about the parts, and when going about attempting to identify and date them. Accordingly, terms need to be solidified, in the same line as a dictionary.

What you can expect to gain from agreeing on whistle parts?

So, we will endeavor to look at some exteriors and interiors to see what makes them different and what makes them alike. This will help in two major ways

- What to use in identifying different manufacturers, including dating the whistles.

- To be able to communicate with others about your whistles accurately.

How this affects the identification process?

Additionally, it is not uncommon to read forums where collectors are grasping for identification by scrutinizing the stamps, lettering and exterior parts, when the inside parts many times can, in short order, clearly identify who made the whistle.

We will look at and into the following whistles — beauforts ( or conical ), tube shaped whistles , escargots ( snail shaped ), rounds, bosuns and circumferential, thereafter creating some discussion about how varietal whistles are made easier — or at least manageable to describe, which can be frustrating by comparison.

Whistle Classification

| Category | Beauforts (Conical shaped) Tube Escargots (French for “snail shaped”) Rounds Bosuns (also: bosons, boatswain) Circumferential |

| Order | Various manufacturers |

| Type | Not applicable |

| Class | Brass Nickel plated brass |

Whistle Archaeology

The first four groups were named or at least formally published by Martin Gilchrist in the UK, who pioneered many guidelines for studying whistles ( — see Collecting Police Whistles and other Types 1998 and More Whistles 2005 ) and wanted to be able to facilitate communication with other collectors and students.

However, not a lot is spent describing boson pipes, as much was already established, having been in existence for hundreds of years. Circumferential is a term originated at the Whistle Gallery to describe bell and other whistles that use the entire perimeter of the ‘window’ tube edge or bell edge to create the whistle sound, rather than a section through a ‘window’.

Some useful terms often used:

- beaufort – conical shaped whistle

- barrel – the body major of escargot whistles

- body seam – early tubes needed to be seamed together, eventually tube stock without a seam was developed.

- buoy – the round bowl at the end of the gun and keel with the small opening for sound on boatswain whistles

- button – used for the sides of escargot shaped button whistles taken from uniforms

- chamber – the inside separation(s) inside the whistle body, as opposed to separate tubes

- circumferential – for describing the entire round body edge that air passes over to make a whistle sound, rather than a small singular window edge.

- diaphragm – separating wall and plate unit above the window(s) in tube whistles to diffuse the air blown through the mouthpiece holding the disc, fipple or wedge.

- disc – flat part below and attached to the separating wall perpendicular.

- escargot – snail shaped whistle ( French name )

- general service whistle – acronym GSW, tube shaped whistle ( those not manufactured for a specifically named use, like police force or fire brigade ), but could be other generally used whistles.

- gun – the long tube above the keel edge of boatswain whistles

- Keel – the flat piece below the gun tube for designs, strengthening connected to the buoy

- knop – top part usually rounded, to hang the chain or string off, commonly with a hole

- loop – the fixed ring attached usually at the opposite end on the whistle from the mouthpiece

- mouthpiece – the sectional opening end which is blown through

- partition – inside the whistle chamber, a division that creates 2 or more chambers

- pea – ‘triller ball’, early on was a pea or stone, cork etc. – not essential for a whistle to work, but causes trilling

- Porteous top – in tube shaped and round whistles the extra rounded top cap of Richard Porteous’ design

- ring – top ring connected through a knop, attachment point, also called the shackle on bosons.

- shackle – the ring attached through the keel next to the mouthpiece on boatswain whistles

- sidewalls – both sides of the escargot of the barrel

- stop hole – a hole in the body usually above the window, for varying the sound as opposed to a drain hole for saliva

- tine – projections from the partition wall to help solder it to the sidewalls

- tooth grip – at the mouth or mouthpiece front edge, as some form of projection to hold the whistle in your mouth hands free, typically on escargot mouthpiece top and/or bottom

- tongue – an inserted piece into the mouthpiece of escargots to keep the mouthpiece from jamming

- top cap – the top of the whistle just under the knop, ring, pillar etc.

- unibody – the forming of a tube with the mouthpiece incorporated as one piece

- wedge – used primarily in beaufort/conicals in the same manner as the disc that is attached to the partition, splitting the incoming air

- window – the hole ( many shapes ) allowing air to escape when blown, exiting against the edge to make the whistle sound

Whistology

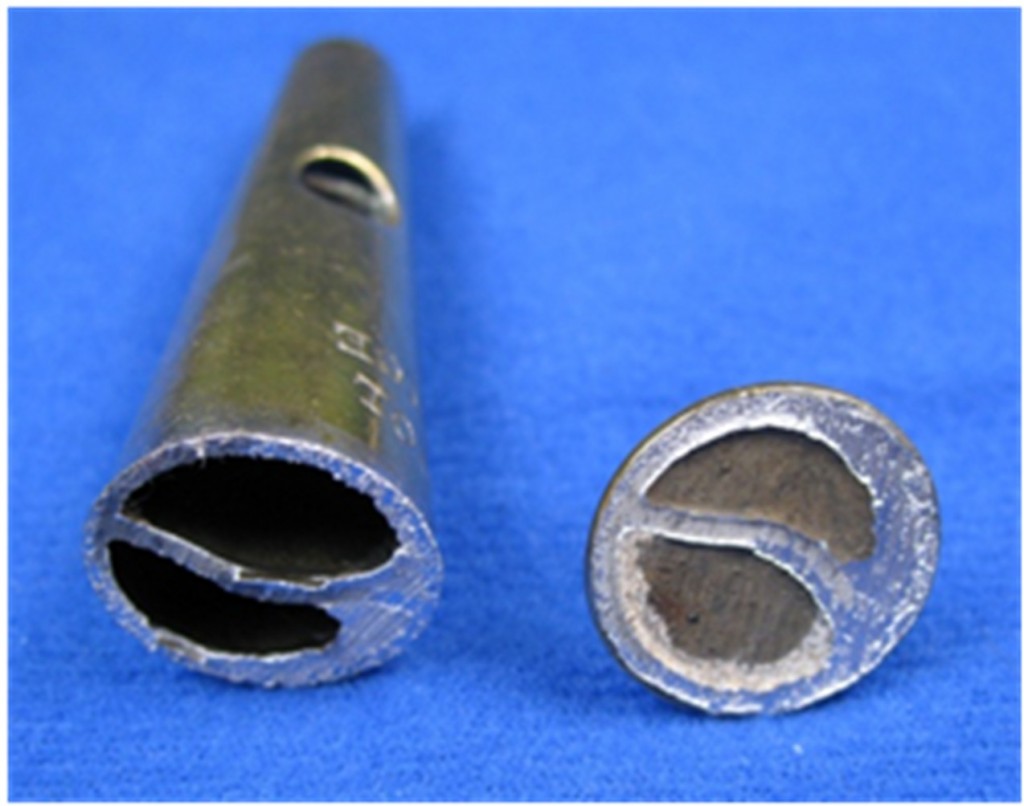

First up, let’s look into a beaufort/conical whistle. It is easy to see that it is conical shaped, and what also makes it different inside from straight tubular whistles is the diaphragm. It is usually a wedge ( rarely seen on only the earliest of tube whistles ) instead of what you commonly see in tube shaped whistles which is a flat disc. On the other hand Hudson developed a flat dis in later manufacturing.

Later in the timeline Hudson did switch to a flat disc in beauforts, most manufacturers never changed however. So occasionally you will see a flat diaphragm disc that is very thick. The sharp part of the wedge faces the hole ( mouthpiece or mouth opening ) where air is initially blown into the cone shaped barrel. Later Hudson whistles were more refined and the disc thinner.

Thereafter, the air is directed out the two holes ( windows ) of the cone, at that time exiting and also at the correct angle to cause a shrill sound. The top is the knop where the chain or lanyard is attached.

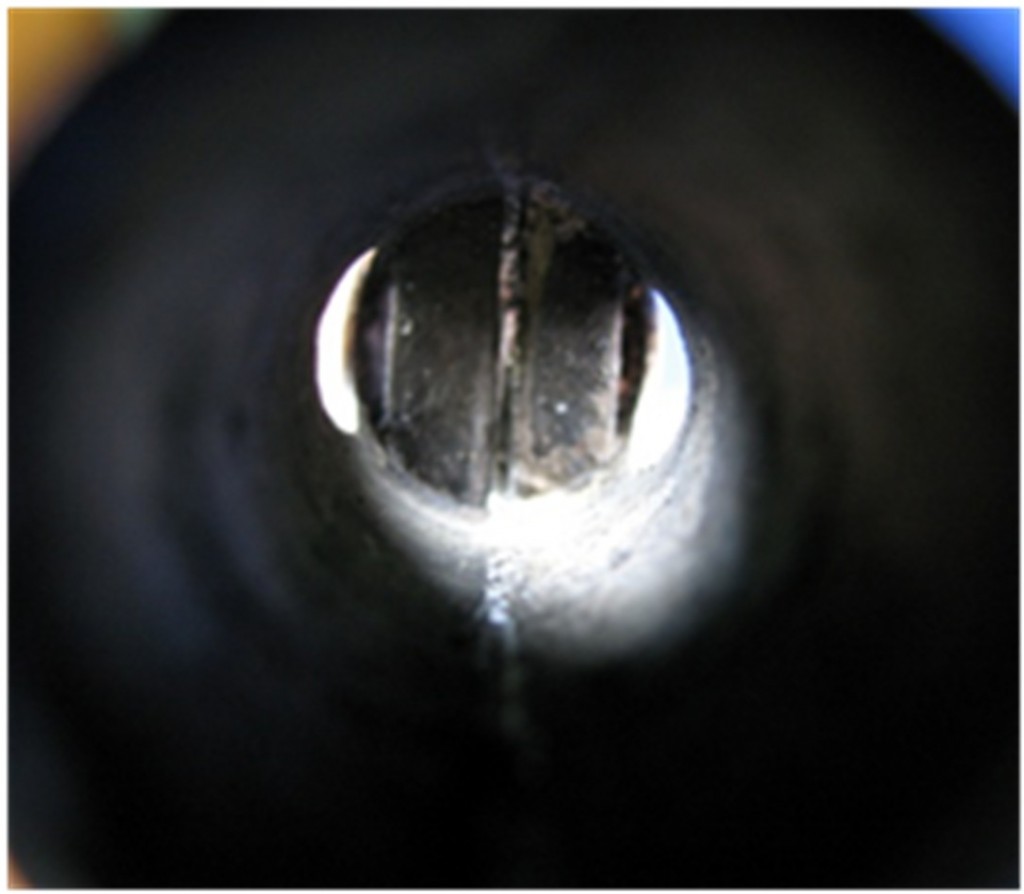

Now, as we look into the whistle you can see where the top is soldered, but also allows us to have access to see a separating piece called the partition which fits into the top groove of the wedge.

Terms learned:

- Beaufort

- Diaphragm

- Wedge

- Mouthpiece

- Window

- Knop

- Partition

If you are looking into the cone from the topside and down, you see the wedge still intact. Then pulled out you can see the wedge shape. You can also clearly see the partition and how it functions.

See the edge of the wedge shape looking up the whistle:

And finally, the parts as they should be installed…

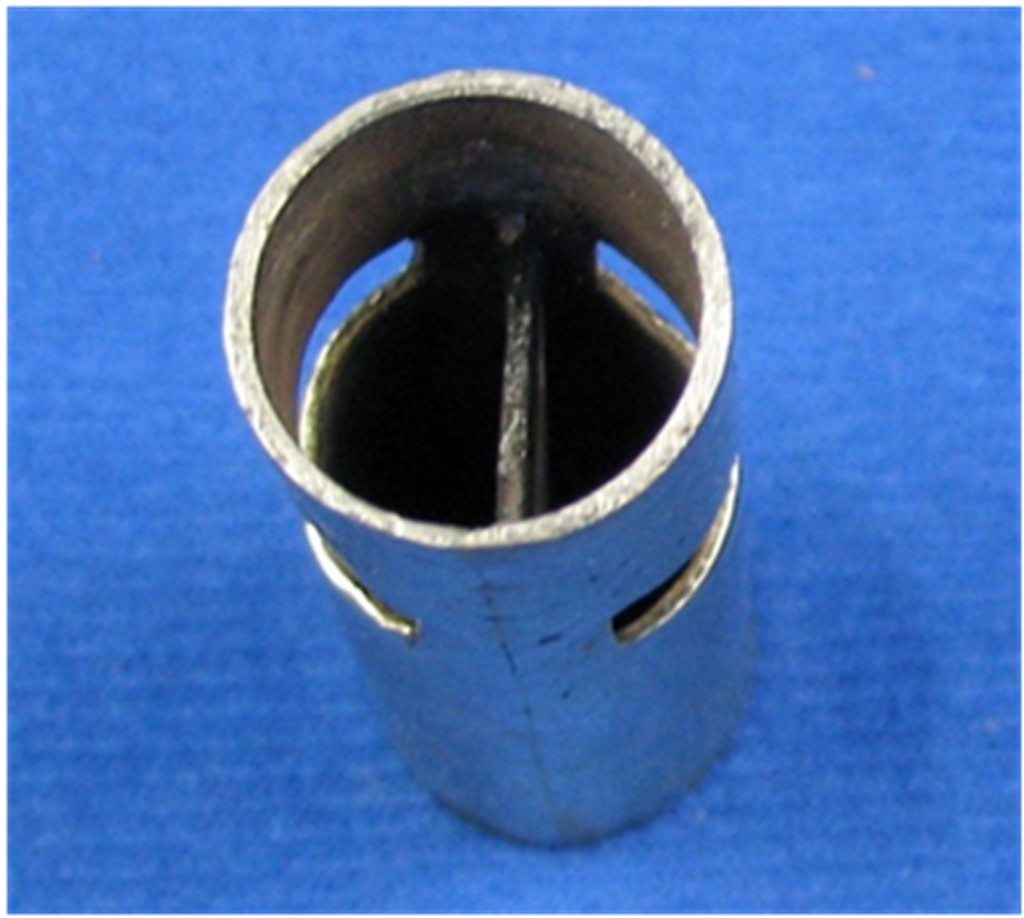

Next we look at the more common general service whistle ( GSW )

You see right away with the tube-shaped design, that the parts can be installed from two different directions when manufacturing. Then the top cap is soldered on as well as the mouthpiece. The mouthpiece was cast in early whistles and later was machined and ‘rolled’ at the edge to cut costs of labor. The seam to the tube could be found between the windows or even through them. Eventually there would be seamless tube stock. Some whistles were made without mouthpieces at all by eliminating mouthpieces in a unibody type whistle.

Inside of whistles are like fingerprints. The manufacturing identifies who the maker was. Indeed, it has been said that the manufacturer can be identified clearly from the tool marks used at each facility. This makes sense and with more whistles identified by other means this would help for whistles unidentified to be tracked down.

The diaphragms or sometimes a simple disc reveals tremendously the secrets of the makers. In More Whistles by Martyn Gilchrist, there are great pictures of whistle diaphragm parts dating to the earliest ones made by Hudson and forward in time. They went from merely cast discs, to stamped ones and each stage of development and patents, helps in dating the whistle as well as the attachment points.

So, let’s break one down.

We will look at a whistle circa 1900. It has a machined mouthpiece.

- F. 1 the whole whistle – a general service whistle or GSW.

- F. 2 is expanded in parts the separating wall is still in place

- F. 3 the top cap which is cast and a flat contact surface.

- F. 4 is the top removed and looking down into the whistle

- F. 5 is looking from the mouthpiece end up into the whistle body, the disc inserted back in

- F. 6 the mouthpiece with rim capable of slipping over the tube

- F. 7 the open end of the mouth with the edges machine curled towards the inside

The manufacture, type, ( cast or pressed ) and placement are all important details.

At first simple discs were soldered into place. They came loose ( or fell out ), so tines were added to attach to the sides. The tines are the long pieces at the top here and faced down towards the mouthpiece. Later they would be split and fit upwards towards the top cap and straddle the partition.

Next is a look at a machined mouthpiece with the front edge ( mouth opening ) ‘rolled’ around the edge to make it smooth rather than a work intensive cast mouthpiece. Compare that to a fully machined one out of the USA that was made from one solid piece of brass on a lathe, which was developed later in the whistle making timeline. Then compare a cast one still attached to a whistle, side by side – all three. All three of these come in variations, but these are the three basics to recognize.

Always remember that guidelines presented here are not rigid rules as to what a manufacturer used and when they used their parts, sometimes even years later.

- Cast – pre 1884-5 ( sometimes they were used later as in oval whistles, King whistles or even from spare parts )

- Rolled- 1885 to present

- Lathe – 1930 and on

Here are a couple pix thrown in. One with a partition that has a disc already attached, no separate diaphragm needed. Then a unibody that eliminates the need for a separate mouthpiece.

Next up are escargots. You might think that they are uneventful and alike. However, there is a tremendous amount of variation, and this makes it even more important to compare or ‘apples to apples and oranges to oranges’, so to speak.

The escargot has several features to be aware of. Historically it was first seen in button whistles, then in the 1880s it lightened up in metal construction, but was similar, yet without actual buttons used for the sidewalls. However, by 1890 there were more parts and heavier cast parts were used in 4,5 &6 piece construction. Finally, these gave way to 3 piece construction of one top ( folded over on each side ) and sides, one bottom and the knop. Additionally there came the inserted piece of the tongue to keep the twitter ball ( or pea ) from jamming. making it a 4 piece whistle again.

Notable parts are the mouthpiece to blow in. The barrel of the body major. The raised top and bottom ridge called the toothgrip(s) which sometimes are exaggerated or even soldered on, but mostly pressed outwards by machines. Each part is useful in identification and at the least categorizing them.

Next, we are looking at an 1885 handmade example for extra discussion. Note this one has under strengthening to support the mouthpiece.

An exploded view illustrates:

- Barrel

- Pea

- Sidewalls (2)

- Mouthpiece

- Under strengthening

- Tooth grip

Compared to post 1900 escargots, there the barrel wrapped around and a lip was inserted ( to keep the ‘pea’ from jamming ). Each of these parts are useful for identifying the manufacturer, dates and variation of models.

New terms learned:

- Under strengthening

- Sidewalls

- Lip

- Pea

- Barrel

- Tooth grip

Lastly, round whistles are just that ( mostly ) they are round, usually with one window. However, it is not unusual to have a stop hole for varying the sound. Additionally, they usually have a mouthpiece with a fipple to fit next to the person’s lower lip.

Round whistles can be cast, made from drilled out solid rod, or machine pressed. Usually, they have but one window. Stop holes may be incorporated, usually not. The knop commonly has a hole, but older ones may have not used one and a string had to be carefully knotted. A fipple was fitted into the mouthpiece hole made of metal, or wood and is inserted, pins were used, solder or other means for retention. Fipples are another means of identification. Sometimes the top cap and knop could be threaded to screw on to the body to make it a two-piece whistle.

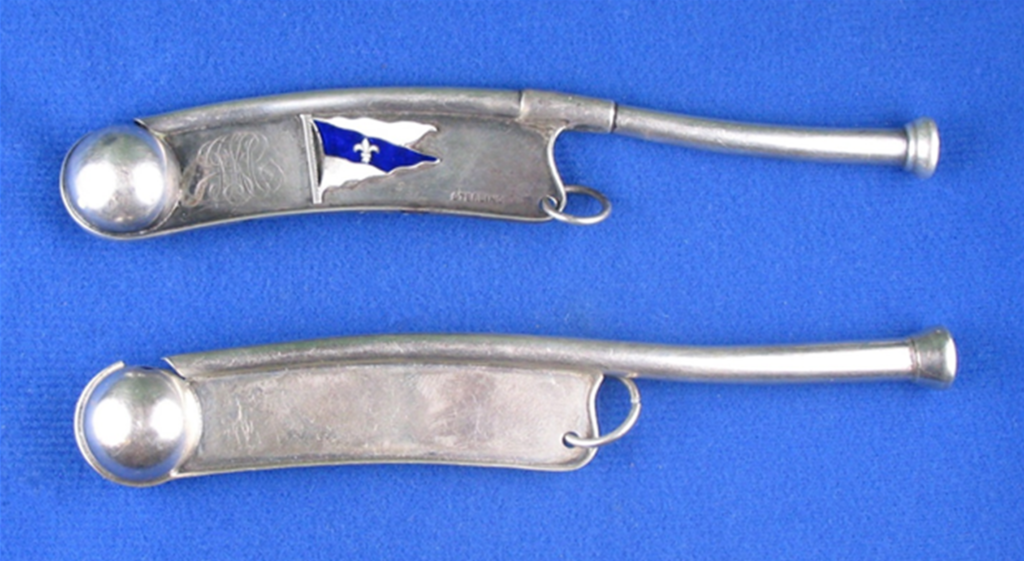

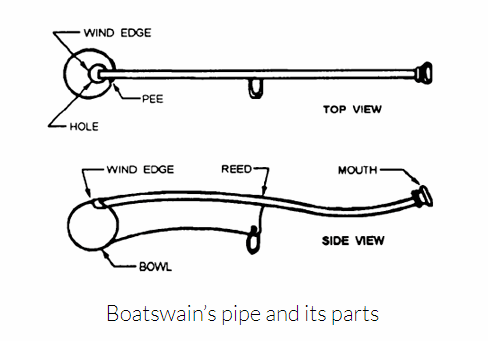

Boson whistles

Boson whistles can be understood by their parts as seen in the diagram. They come in many models but follow these guidelines.

Circumferential Whistles

This is the principle of circumferential windows. Note the edge from a bell whistle accepts air around the entire edge.

Hope this helps to kick off things for you. Looking at rounds, escargots, bosons, and circumferential whistles is pretty obvious how they work. It’s easy to see inside them. There are quite a few construction techniques that developed over the years of manufacturing, but for the most part they are all easy to see inside, as the windows are large. You may want to get a good small flashlight though. Construction techniques were merged, overlapped, and combined over many years and manufacturers, so don’t get too rigid in your thinking.

Finally some things you will eventually want to acquire are:

1) flashlight ( we also use a fiber optic light )

2) magnet for testing for steel and iron

3) calipers – inside and outside

4) scale

5) brushes – fine bristle, toothbrush and also brass as it doesn’t scratch when it cleans built up dirt and oxidation

6) magnifying glasses and especially head gear

7) picks ( we like dental ) and tweezers

8) polishing cloths

9) pliers ( flat smooth ) needle nose and jewelers flat vise type

10) glue, solder and epoxy

11) camera especially capable of close ups

12) air cans

13) tags of some sort

14) computer

15) oil – we use olive oil for conditioning wooden fipples

Conclusions:

Descriptions of whistle parts may seem unimportant, until you start to study the whistles. Good communication follows with understanding. Here is a good reference.

TWG

Posted November 11, 2012

Revised May 16, 2018

Revised October 10, 2020

Revised February 12, 2021

Revised December 27, 2021

Revised December 29, 2021

Revised January 30, 2022

Bibliography:

Collecting Police Whistles and Similar Types, by Martyn Gilchrist and Simon Topman 1998

Reference Collection Whistle Gallery

More Whistles, Martyn Gilchrist 2005

http://www.militarywives.com/index.php/what-do-the-boatswain-pipe-call-sound-like http://www.dundasseacadets.com/uploads/9/8/1/8/9818667/boatswains_20call.pdf

© – All photos with blue background property of The Whistle Gallery reference collection. Please contact The Whistle Gallery for permission of use of any website content. Spotlight articles are copyrighted. Please contact The Whistle Gallery for permission of use of any website or Spotlight article material written or otherwise. Use of photos without authorization is prohibited.

Where to Learn More:

Spotlight > Whistle Maker by Country > United Kingdom > Hudson

Spotlight > By Whistle Category > Conical Whistle Articles (Beaufort)

Spotlight > By Whistle Category > General Service Whistle Articles

Spotlight > By Whistle Category > Escargot Whistle Articles

Spotlight > By Whistle Category > Button Whistle Articles

Spotlight > By Whistle Category > Round Whistle Articles

Spotlight > By Whistle Category > Boson Whistle Articles

Spotlight > By Whistle Category > Bell Whistle Articles (Circumferential)