Spotlight > By Whistle Category > Escargot Whistle Articles > 010 Interlocking Teeth Escargot USA

Whistory

Among described American whistles, is a uniquely designed escargot. Unique, in that it is the only one that employed advanced interlocking teeth to connect the barrel to the side plates on escargot whistles.

The construction characteristics of interlocking teeth in whistles

In the earliest models there were 7 interlocking teeth per side, 5 at the edges, two on the side walls. So within a few years simply 3 and finally 1 per side plate. Rarely none altogether.

The earliest models used 2 perpendicular side interlocking teeth directed into the interior tongue plate, which was added to keep the cork ball from jamming, accompanied with 5 more rim teeth. Apparently, the cost of labor of this robust design, must have caused the manufacturer to cut back in production techniques. Only one escargot by this maker has been found without interlocking teeth by TWG.

Where and who made the interlocking teeth whistle design?

It enters our SPOTLIGHT, having been made by an unknown manufacturer. It is never stamped with made in the USA, so may or may not have been an import. There are other manufacturers outside the USA that utilized this interlocking tooth concept, but did not develop this concept as extensively.

After the initial release circa 1914-16 it improved from a rough start of nickel-plated brass, changing to German silver ( nickel silver ). ( The mid-sized model was listed as plated brass ). This larger escargot was bulky and heavy at first, this in turn gave way to a lighter construction, yet sturdy due to the rimmed interlocking teeth and improved workmanship.

Whistle Classification

| Category | escargot |

| Order | unknown maker |

| Type | sporting goods companies |

| Class | nickel silver nickel plated brass |

| Subclass | interlocking 7, 3, 1, no teeth |

Whistle Archeology

No information pertaining to the maker, the back ground, location, or why all their whistles were aimed at sporting good distribution.

Whistology

We have designated three escargot groups and dates as follows:

| Group A | 1914 – 1922 Large size 7 teeth per side 1914 the beginning of the Wilson name |

| Group B | 1923 – 1926 Large size 3 teeth per side ( a Winchester 1806 is first seen in a 1923 Winchester catalog ) |

| Group C | 1923 – 1928 Mid size 3 teeth per side ( a similar style Winchester 1805 is listed in the same catalog ) |

| Group D | 1926 – 1928 Large size 1 tooth per side Arbitrary dates |

Escargot, Group A

Group A dates from 1914 – 1922 and is always nickel-plated brass, with a rather rough construction. It always has 2 teeth protruding sideways ( pictured with arrows ) and interlocking with the sides besides the 5 rim teeth. 7 teeth total.

Escargot, Group B

Group B from 1923 – 1926 and is always nickel silver and lighter weight, very well constructed. It was a marked upgrade from the previous Group A. Early ones were large, full size escargots or what has become known as the larger Glasgow escargot.

Escargot, Group C

Group C A mid-sized Glasgow model with a different type and identifiable knop altogether, would appear at the same time. Nothing new to the overall body manufacturing except for thinner construction. The primary interlocking teeth occurring only at the edges where the sides connect to the barrel. Mid-sized whistles were always nickel-plated brass.

Escargot, Group D

Group D is reserved for the larger Glasgow size that seems to be the last manufactured date as the teeth have been reduced to one each side and the fold inside the tongue has been eliminated.

The knops in early ones circa 1916-1922 ( Group A ) were round ( left ), whereas the ones dating after that had slightly flattened sides to the knop top ( Group B ). Occasionally a whistle from Group B would find a round knop installed. Granted it is not much of an variation, but seems to be unique to this maker. Even more unique is the mid-size model with the shorter pillar top knop shown ( Group C ).

The dates have somewhat been established from a 1923 Winchester catalog here at The Whistle Gallery library but cannot be rigid dates. The 1923 catalog shows a round knop in the picture P1806A. However, it is the first occurrence of a Winchester 1806 in a catalog. No Winchester stamp has been seen on a 7 tooth earlier whistle. The 1805 is a mere listing P1805A

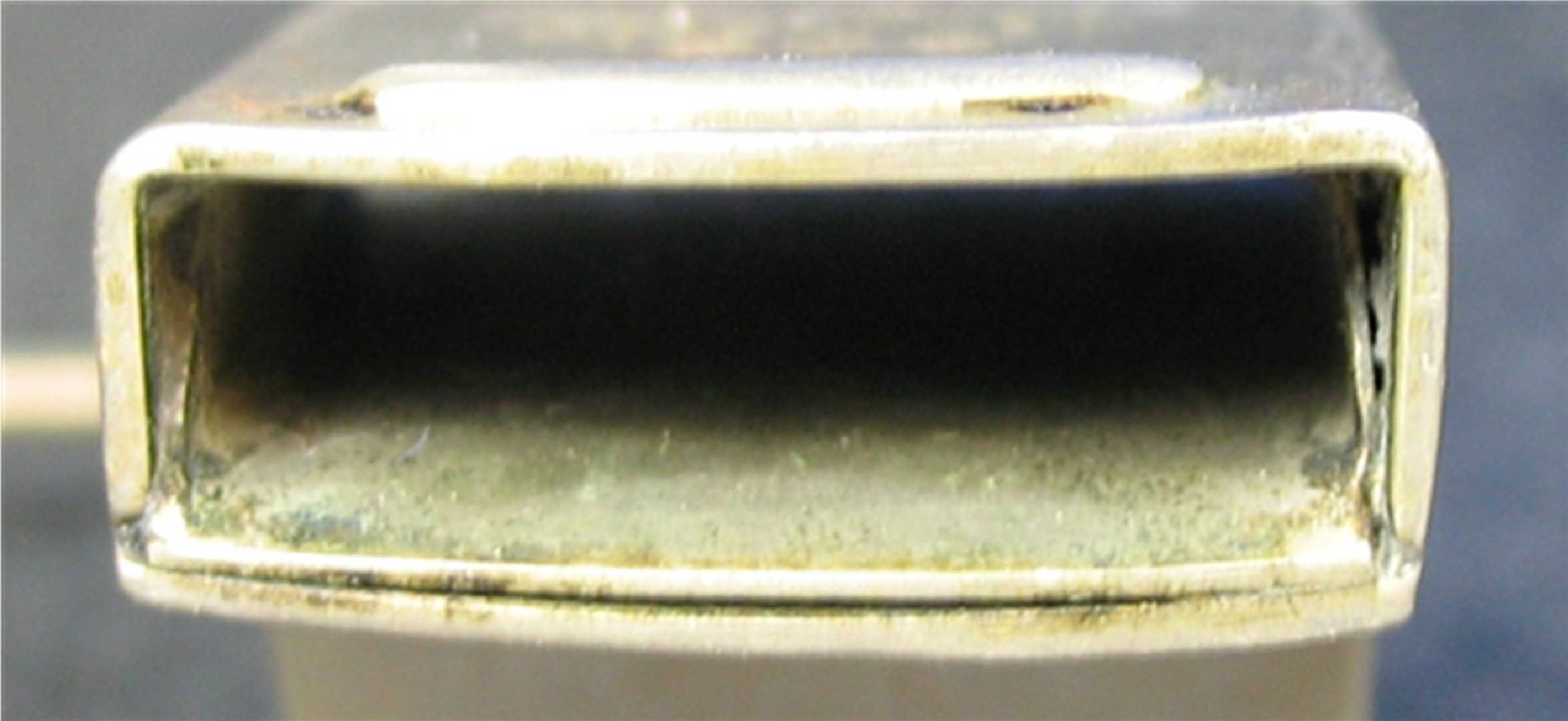

We should also discuss the distinction of this very well-made model in the ‘U’ shape of the tongue inserted inside the mouthpiece. This occurs only in Group B and Group C models. The earlier versions were made in a much ‘rougher’ design which was thicker and soldered poorly.

Pictured here is the feature not seen to date in other escargots, is the tongue inserted into the mouthpiece ( not unique in itself ) wrapping up the sides of the mouthpiece. This was also used to wrap down over the inside of the round barrel to keep the cork or wooden ball from jamming into the exit hole of the air when blown. Much like the diaphragm in GSWs ( general service whistles ) it is a useful tool in determining manufacturers.

Looking inside the MP end one sees that the sides actually fold up on each side ( as seen in this Winchester 1806 large model here ) where extra support is created by being in contact with three sides of the four walled mouthpiece. This innovation was used in both large ( Group B ) and midsized models ( Group C ). It dates from 1923 onward. It is not found in Group A whistles dating from 1914-1922.

Note the sides that fold up and also the 45 degree cuts slanting toward the back.

Now let us examine group A in regard to the interlocking sections or teeth and also the locking teeth on the sides which made this early designed whistle a very rigid construction.

We’ll start with the interlocking teeth of which there are SEVEN total per side (Group A ). Each ‘tooth’ measuring 3mm wide and not quite flushing with the top edge.

They are evenly spaced commencing just below the mouthpiece and progressively getting further apart till reaching just above the window ( 5 ). Picture left, ‘teeth’ interlock, picture right side teeth (2). In summary 5 teeth at the rim and 2 teeth exiting the sides perpendicular from the tongue which make up the interlocking connections.

Now look at the actual interlocking sections. The manufacturer would go on to reduce them to three per side ( and then down to one per side ) apparently finding that much of this work was redundant or too expensive in labor, machining etc.

The teeth extending sideways were very innovative in that they were actually aimed at supporting the tongue itself, making the soldering even further secure. The wider tooth was from the long side to the tongue through the side wall.

The second tooth extended from the tongue as it curved down into the barrel so that the two teeth were close to perpendicular to each other creating a very sturdy whistle.

Here is a close up of a single tooth located at the top position of the window edge. One only to each side was the reduction chosen close to the end of this series, with four different stamped examples known.

| Known stamps are: | |

|---|---|

| GROUP A | 7 teeth per side — large Glasgow escargot – plain, no stamp – Goldsmith – Referee – upside down – Signal Police – Thomas E. Wilson – Reach |

| GROUP B | 3 teeth per side — large Glasgow escargot – Dardevle – D&M sporting goods – Goldsmith – Reach – Referee – upright – Thomas E. Wilson – Winchester 1805 – large – Winchester 1806 – large – Wright & Ditson Victor Co. |

| GROUP C | 3 teeth per side — midsize Glasgow escargot – Winchester 1805 – med – Optimus – med – Referee – med – Goldsmith – med |

| GROUP D | 1 tooth per side – large Glasgow escargot – Reach – Goldsmith – Referee – Thomas E. Wilson |

| *** Reach circa 1914-22 ( large ) found without any interlocking teeth ( large ) |

Conclusions:

From the outbreak of WW1 to the time of the great depression, a remarkable escargot whistle was marketed in the USA. It had interlocking teeth on the side walls. It was improved within a short period of time and expanded to two models.

It had a wide distribution in the sporting goods line and yet disappeared by the great depression. We have as yet to see more stamps appear and as of this revision. The manufacturer, whether in this country or another is yet to be discovered., however it appears to be made in the USA. All of the stamps were focused on sporting goods companies, the exception being Optimus ( camping equipment ) closely akin.

TWG

Posted April 5, 2013

Revised November 22, 2018

Revised August 15, 2020

Revised October 11, 2020

Revised February 12, 2021

Revised February 13, 2022

Bibliography:

1922 Winchester catalog reproduction

Reference Collection Whistle Gallery