Whistory

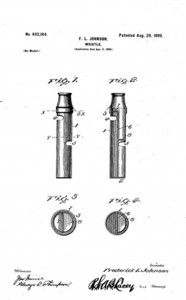

This SPOTLIGHT looks at split level windows in whistles. This is not a new concept of varying the heights of windows, dating back to Thomas Yates circa 1870 in the UK, then forward to Coney & Co. circa 1880-90. It is especially seen in F.L. Johnson’s patent of 1899 in the USA.

The impact of this change to split level windows in whistles

The requirements for this to work is not just changing the window heights as in the Yates whistles. There needed to be internal alterations of the diaphragm and separating wall to match. This made the whistle more expensive , complicated and therefore higher quality by nature.

Not many models are known or at least have not been collated and presented, so here we will look at some 6 examples.

How the split-level windows of whistles developed

Initially Yates used this concept to combine two notes with a GSW (general service whistle) circa 1870.

We will note the right window is slightly below the left window. Yates at first used a wedge design that varied enough to meet the two window heights. This sound certainly predated Hudson’s famous Metropolitan two note claim to fame.

Coney ( UK ) made a very high quality whistle with split level windows. No patent information is known at this time, although Coney held several patents of corkscrews. They also stamped PATENT on a split level whistle, no one has found that patent information yet.

It can be difficult to date the split-level window GSW for Coney as the company dates back before Gilchrist’s estimate of 1900s in CPWs, so for now we will date it circa 1880-90. On page 93 of Collecting Police Whistles by Martyn Gilchrist a good drawing can be seen under Diaphragm X to see the soldering work. Then go to page 81 and look at an example. The mouthpiece and top rings are distinct in identifying Coney’s. Shown is an example from The Whistle Gallery reference collection.

Whistle Classifications

| Category | split level windows |

| Order | Thomas Yates John Coney F.L. Johnson Unknowns |

| Type | GSWs Cycling |

| Class | Tin Cast Machined |

| Subclass | wedge diaphragm stepped diaphragm disc |

Whistle Archeology

This patent is from the USA, but was undoubtedly superseded by Thomas Yates in the UK.

Whistology

UK, Coney GSW

Coney would find an improvement to this concept and become renowned for it. This would be 10 to 20 years later, circa 1880-90 ? The inside stepped disc is cast. The windows are hand filed.

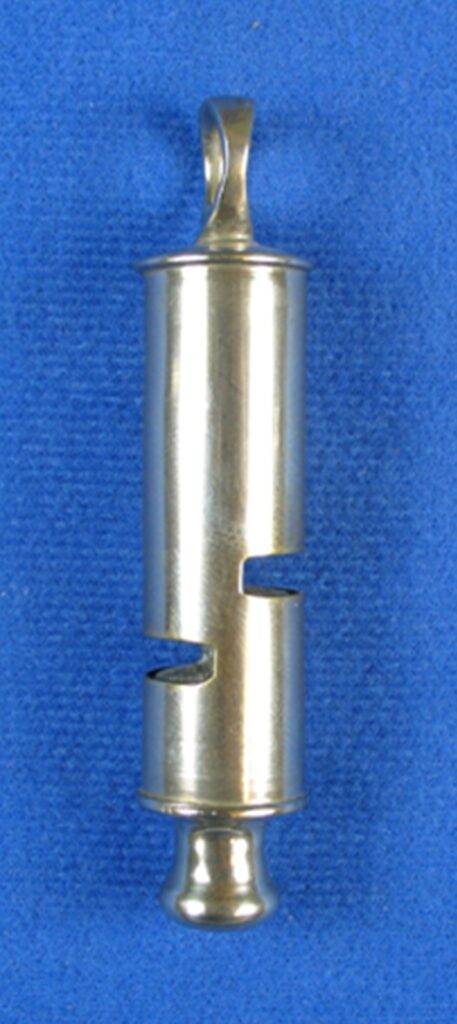

USA, F. L. Johnson GSW

Next up in the timeline is a look back to a known patent by F.L. Johnson from the USA – 1899. An American inventor who held several patents for whistles. He was located in Wallingford, Connecticut.

Connecticut was a real hotspot of industrial and for whistle manufacturers and patents circa 1880-1900. This split-level dates to 1899 and was a different longer model altogether. There are no cast parts, and it is light weight.

Note how the drawing shows the internal adjustments to the diaphragm. It will be interesting to see if this design was used in Germany or France in their pre 1900 productions. ( The Nick Harris looks to be possibly German made, although distributed in the USA, like many Municipal stamped police models )

UK, Coney-Hudson GSW

The cuts come clear into the window edges so as to reach the diaphragm making the window width as extreme as possible. The windows are thinner than many GSWs. The following split-level whistles followed Coney’s pattern in GSWs.

So we progress in time after Coney was purchased by Hudson to the clone by Hudson ( UK ) also mentioned in Martyn’s book on page 81. Two similar stamps are described on page 81.

However, Coney used the T.E. Thompson stamp on their own whistle that easily differentiated from the Hudson made split level, even with the same stamp.

Both are stamped Coney’s Alarm. However, this one also has T.E. Thompson & Co. Ltd. and Calcutta Ld.

What differences do we note?

- Rolled mouthpiece, not cast

- Two piece not stamped out and connected, not cast

- Nickle plated brass, rather than brass or nickel silver

- Thicker flat cap

Harris GSW

Now we move over to the USA where a heavy, bulky version with split level windows was distributed. It was made to promote the Ed Harris detective agency. We wrote them to try to find out who manufactured the whistle for them (hopefully from their records ) but were kindly rebuffed. It appears and feels heavy and to a certain degree, bulky.

The Coney weighs in at 37g while the Hudson’s made comes to 3g. However, the Nick Harris weighs in at a 57g or 20g more than the Coney. Seeing how the mouthpiece and top ring are actually made out of lead it is not surprising. This whistle should never had been made of lead and then put in the mouth. This construction has mainly been seen of German made whistles marketed in the US circa 1915-25.

The sound is much more shrill than the other two. Neither Coney nor Hudson utilized tines up from the diaphragm along the partition edges to contact the tube side walls for support, but the Nick Harris uses extended tines on both sides. All three appear to be cast mouthpieces and top rings. Lastly this example shows much less variation in the window positioning, lending to the closer more shrill sound.

USA, unknown manufacturer

We will finish out by looking at a very unusual split-level model found in the USA manufactured entirely of machined brass parts. Weighing in at 40g, it is closer to the originals in weight that we started with. The two levels are well split and the sound comparable.

Interestingly the top ring is machined in one direction to make the cap and then machined in the other direction to make the ring. The ring rests high up on the top cap like the Coney does. Moving to the mouthpiece we see it is clearly machined inside and out leaving a slightly larger opening.

Looking inside is where the real surprise is found. The diaphragm disc and partition are actually riveted together twice to hold the partition together. This is the first time we have seen this done.

Now let’s compare the last four together. you will see fairly similar lengths, however some variations in the windows, especially the Nick Harris. The sounds are directly proportionate to these levels although the construction is similar.

Just for fun we examine this four-window whistle from Germany. Inside the diaphragm is divided into four levels yet the windows are at the same level. It does not carry the sound that the actual window splitting does.

Conclusions:

Split level with dissonant sounds preceded Hudson’s claim in the 1880s to a unique sound. The internal requirements set these apart from standard GSWs.

TWG

Posted July 8, 2012

Revised May 19, 2018

Revised October 10, 2020

Revised February 12, 2021

Revised December 27, 2021

Revised December 29, 2021

Revised January 30, 2022

Bibliography:

Reference Collection Whistle Gallery

Google patent search

Collecting Police Whistles by Martyn Gilchrist and Simon Topman

© – All photos with blue background property of The Whistle Gallery reference collection. Please contact The Whistle Gallery for permission of use of any website content. Spotlight articles are copyrighted. Please contact The Whistle Gallery for permission of use of any website or Spotlight article material written or otherwise. Use of photos without authorization is prohibited.

Where to Learn More:

Spotlight > By Whistle Category > General Service Whistle Articles

Spotlight > By Whistle Category > Cycling Whistle Articles

Spotlight > Whistle Maker by Country > United Kingdom > Yates

Spotlight > Whistle Maker by Country > United Kingdom > Coney

Spotlight > Whistle Maker by Country > United States > F.L. Johnson

Users This Month : 510

Users This Month : 510 Total views : 147592

Total views : 147592