Spotlight > Whistle Categories > Siren > 134 Sirens, Part IV: Thin Wall Sirens

Whistory

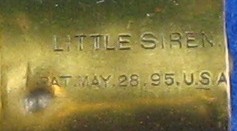

This SPOTLIGHT is the fourth in a series “Sirens, Part IV: Thin Wall Sirens” and concludes the series on sirens (I: Case, II: Variety, III: Torpedo, IV: Thin Wall). We learned previously that Case sirens and Torpedo sirens were patented in 1895, case sirens in the UK and Torpedo sirens in the USA. Thin wall, sometimes called tin sirens, were also patented in 1895, but in the USA.

Why so many thin wall sirens?

By comparison, thin walls are less expensive to make and much more variable within this class. The mechanism can be pressed into many configuration. Therefore much can be done with figurines beyond the original shell design.

The case siren and torpedo siren both have similar wheels inside, whereas the rotor in thin wall sirens is pressed out vents, rather than drilled holes. Was there anything that led up to three countries simultaneously inventing these models the same year? It could perhaps be the previous patent of 1893 by Eli.

The impact on advertising may not have been anticipated, nor on the toy industry, yet it becomes undeniable over the decades following, so much so that it is difficult to capture the scope. Our intent with this article is to record a structure of study to launch from. Many pictures presented are from the internet and will need credit, but they will touch on the variability achievable with the pressed wheel concept in sirens.

What are the earliest manufacturing connections of thin wall sirens?

Mossberg Wrench Company

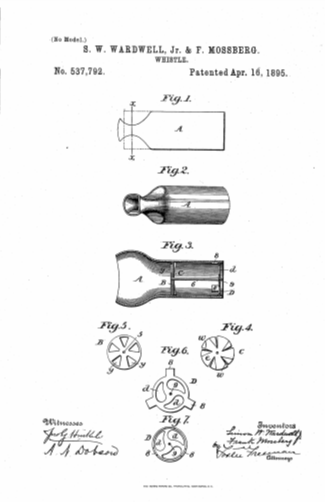

In the 1890s Mossberg wrench was manufacturing several styles of adjustable bicycle wrenches. Assignments for wrenches were assigned to the Mossberg Wrench company, so it is not surprising that the siren patent was also aimed at the cycling markets.

Wardwell is listed in 1897 on a wrench patent as an officer in the Mossberg Wrench Company by a patent attorney Foster Freeman and by 1906 Mossberg Wrenches is registered with Simon W Wardwell as President.

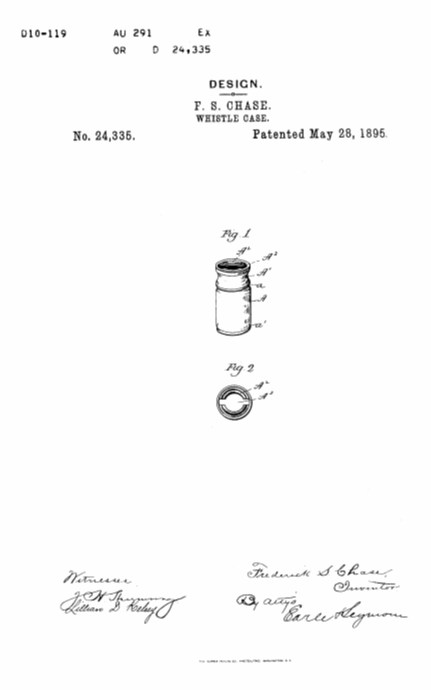

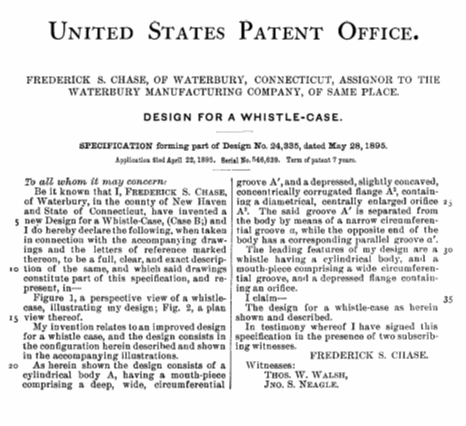

Waterbury Manufacturing Company

In 1890 F.S. Chase was president of the Waterbury Manufacturing Company.

The trade name The Develine was stamped on all three named cities on the Mossberg sirens — Central Falls, R.I., Attleboro, Mass., and Providence, R.I.

Chase Manufacturing Company

At some point B&R took over sales as an outlet with their stamp on the large and medium model sirens. Waterbury Manufacturing had likely rolled into Chase Manufacturing Company by then.

Whistle Archeology

| Category | thin wall sirens |

| Order | Mossberg Wrenches Waterbury Manufacturing Chase manufacturing Perry and Company London Unknowns |

| Type | alarm cycling toy drummers trap |

| Class | nickel plated brass tin steel |

| Sub class | large medium small caricatures |

Whistology Archeology

Mossberg, Locations

- Attleboro

- Providence R.I. ( Rhode Island )

- Central Falls

History

- Frank Mossberg born Wermland, Sweden born 1858, dies 1953

- Simon Willard Wardwell Jr Grantswell Rhode Island born Sept. 3,1849, dies Feb.19, 1921

- Frederick Starkweather Chase born 1862, dies 1947

- Martin E. Trollen assigned his patents to Brown & Bigelow

Timeline

- 1882 immigrates to USA

- 1889 Mossberg Manufacturing Company – Attleboro, Mass

- 1890 ? Mossberg Wrench Company – operated till 1915 independently

- 1895 Mossberg/Wardwell patent siren – assigned to Mossberg Wrench Company

- 1897 reorganized – Mossberg & Granville Manufacturing Company

- 1899 Frank Mossberg Company – Providence, Rhode Island

- 1900 “ — Attleboro, Mass

- 1901 merged

- 1902 moved to Central falls, Frank Mossberg disassociates himself from The Wrench Company ? ( Not to be confused with Oscar Frederick Mossberg of Fitchburg Mass at Ivor Johnson arms and cycle works – 1886 )

Patent, Use/Purpose

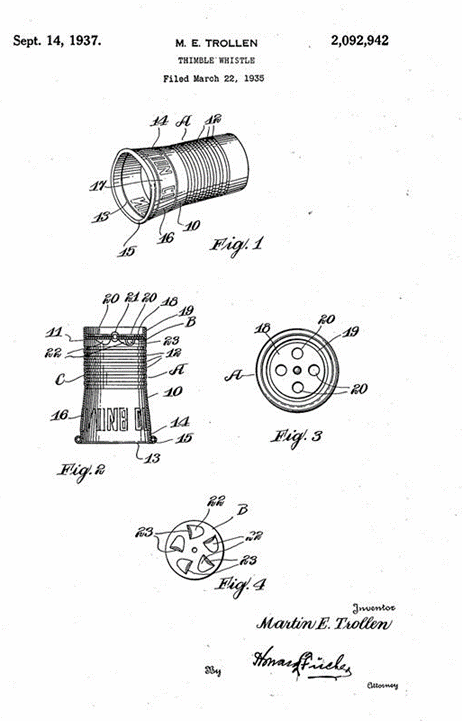

Assigned to Brown and Bigelow 1937

Pat Pending “THIMBLE WHISTLE Filed March 22, 1935 Patented Sept. 14, 1937 zayii'” UNITED STATES THIMBLE WHISTLE Martin E. Trollen, St. Paul, Minn., assignor to Brown & Bigelow, St. Paul, Minn., a corporation of Minnesota Application March 22, 1935, Serial No. 12,432″

This invention relates to a whistle wherein the body portion of the same is made in the form of a thimble. This whistle is designed to make a siren-like sound when air is forced through the same.

A feature resides in providing a whistle having a tubular body portion with a series of annular ribs formed therein which provide reinforcing in the body, as well as grooves which permit the whistle to be held more easily in the mouth of the operator.

A further feature of my whistle resides in its simple construction wherein the open end is flared outwardly and provided with an annular 13 reinforcing bead around the same. The other end is formed with an integral inset transverse wall providing a reinforced annular flange about the same.

This gives rigidity to the other end which carries the wall and the wall provides a support for the vaned rotor of the whistle. The wall which carries the rotor is perforated so that air may be blown against the vanes of the rotor causing the same to spin in the operation of the whistle.

The whistle is designed to provide a means of advertising having a space in the flared end upon which advertising may be embossed in any desired decorative manner, and thus a toy whistle may be made having a utility of forming an amusement for children as well as displaying advertising matter or other display indicia. The rotor is enclosed and protected by the reinforced structure of the inset end wall and the whistle is of a design and character which makes it desirable to give to children for amusement.

Patent, The Build – Casing

The whistle is designed to provide a means of advertising having a space in the flared end upon which advertising may be embossed in any desired decorative manner, and thus a toy whistle may be made having a utility of forming an amusement for children as well as displaying advertising matter or other display indicia. The rotor is enclosed and protected by the reinforced structure of the inset end wall and the whistle is of a design and character which makes it desirable to give to children for amusement.

In the drawing forming part of this specification: Figure 1 illustrates a perspective view of my whistle.

Figure 2 is a vertical cross-section in elevation.

In Figure 3 is a top view of the same.

Figure 4 illustrates the rotor removed from the whistle.

The whistle A may be made of any suitable material and is formed with a thimble-like body portion 10 having a cylindrical part 11 in which a series of annular reinforcing grooves 12 are formed.

The open end 13 is formed by flaring the side wall outwardly at 14 and a reinforcing bead 15 is formed about the open end 13.

The flared portion 14 may be embossed with lettering or indicia 16 to add to the utility of the whistle A as well as the attractiveness thereof. In forming the embossed indicia 16 the background 17 about this indicia may be colored by enamel or other suitable material of different shades.

An inset transverse wall 18 is formed in the cylindrical portion II opposite the open end 13. The wall 18 is integral with the body 10 and in forming the same as illustrated in Figure 2, an integral annular reinforcing flange 19 is formed about the wall 18.

The wall 18 is formed with perforations 20 to permit air to be blown through the same.

Patent, The Build – Rotor

A disc rotor B is adapted to be held by the rivet 21 in a manner to permit it to spin freely when air is blown through the openings 20 against the same. A series of air vane pockets 22 are formed in the rotor disc B which have an air escapement opening 23 along one edge and at the bottom of the pockets 22.

The whistle A is formed to provide a desirable and practical toy to give to children, having in mind a construction wherein there will be no sharp edges or parts on which a child might become injured in carrying the same in the mouth while operating the whistle. The body is of an elongated tubular nature and the ribs 12 form a means which permit the child to engage the whistle with the lips and teeth so that it will not easily slip into the throat.

Further, the rotor B is within the body of the whistle and is protected by the reinforcing flange 19 so that the whistle will stand considerable abuse without affecting its operation. Further, the flared end does not only provide a means of carrying display indicia, but also acts as an enlarged portion to prevent the whistle from easily slipping into the child’s mouth.

Patent, Operation

The whistle is operated by blowing upon the end carrying the wall 18 which causes air to pass through the openings 20 into the vane pockets 22, causing the rotor B to operate rapidly while the rush of air through the same whirls in the ribbed chamber C and out of the opening 13, giving a whistle sound in the nature of a siren.

The character of the sound can be varied in accordance with the formation of the pockets 22 or such other design of vanes as may be desirable formed upon or in the rotor B.

My whistle is of a simple design and it may be made within the scope of the following claim with such variations as may be readily apparent to those skilled in the art.

Martin E. Trollen, Patent Claim

I claim: A thimble whistle including an outer wall comprising a cylindrical shell portion and an integral outwardly flaring shell portion, an annular bead at the outer end of said outwardly flaring portion, spaced annular grooves in said cylindrical shell portion, the end of said cylindrical shell portion at the opposite end of said wall from said bead being folded back upon itself to form an internal reinforcing portion…

….said reinforcing portion terminating in a transverse end wall spaced by said reinforcing portion from the end of the outer wall, said end wall having angularly spaced openings therethrough, a rotor centrally pivoted to said end wall, and pockets formed on said disc to change the direction of air blown through said openings in said end wall to cause rotation of said rotor when air is blown through said openings.

Whistology

Thin wall variations after the Mossberg patent 1895.

Vents play an important identifying feature.

picture credit Chris Mattison collection

Photo credit unknown

Photo credit unknown

Note the different sizes by B&R.

The following toy sirens were gathered from the net and deserve credit if sent in…

Conclusions

Although seeming less in quality, these thin wall sirens proved to be more powerful in the wide applications that could be used in the small toys market. We included cast in this category.

Torpedoes dropped off as well as many case sirens, yet thin walls have endured, albeit inexpensive, cheaper sirens. They are made from inexpensive metal, wood, plastic, paper or whatever could hold the pressed vented wheel.

TWG

Posted August 5, 2022

Bibliography:

The Whistle Gallery Reference Collection

TWG Archives

Google Docs

© – All photos with blue background property of The Whistle Gallery reference collection. Please contact The Whistle Gallery for permission of use of any website content. Spotlight articles are copyrighted. Please contact The Whistle Gallery for permission of use of any website or Spotlight article material written or otherwise. Use of photos without authorization is prohibited.

Users This Month : 510

Users This Month : 510 Total views : 147592

Total views : 147592